SCCInsight: West Seattle Bridge inspection reports shed light on issues and response

Inspecting the cracks inside the West Seattle Bridge Girders.

Mon, 04/13/2020

Editors Note: This article originally appeared on SCCInsight.com on April 9. Its analysis and examination of the causes of the cracks that led to the closure of the West Seattle Bridge are comprehensive and based on a careful reading of inspection reports filed by SDOT. It is reproduced here with permission.

By Kevin Schofield

On Tuesday, SDOT released about a dozen internal inspection reports and other documents related to the cracking in the West Seattle Bridge that led to its sudden closure. Taken together, the documents paint a better picture of the origins of the cracking and how the department has responded since it first became aware of serious cracks in the structure in 2013. SCC Insight also interviewed SDOT’s Bridge Group Supervisor Matt Donahue this morning, who filled in more details.

For background, here’s my previous article explaining how the bridge was constructed and some of the obvious potential issues with its design.

There are three important questions to try to answer:

- Why did the cracks appear in the bridge?

- What has the city been doing about it since 2013?

- Knowing its current state, what are the options moving forward?

Why did the bridge structure start cracking?

First, we need to be clear that over the life of a concrete structure, cracks will appear; it’s in the nature of concrete. But there is a long list of potential reasons why concrete in a bridge might crack, including:

- “Dead load” — the weight of the bridge itself, upon being built, is heavier than expected, and might exceed in some locations the amount of force that it was designed to withstand.

- “Live load” — the weight of traffic on the bridge exceeds the design limits, or is distributed in a way that might lead to “torsion,” i.e. twisting, because some supports are carrying much more weigh than others. This is a concern for the West Seattle Bridge because of the seventh lane that was added later that puts more weight on the south side of the bridge (and the south side has seen a bit more cracking).

- Post-tension losses — this is a catch-all for what happens over time as the bridge settles in. The steel tendons holding the bridge could stretch or relax a bit after the bridge is fully assembled. The concrete can shrink as it fully dries and loses some water. Concrete can also “creep” or sag over time — particularly in the early days after it is cast. All of these things can change the shape of the bridge, increase forces on some areas, and decrease them on others.. Donahue says that they have seen both shrinkage and creep on the bridge, both of which contribute to the observed cracking.

- Seismic displacement — i.e. earthquakes. The force of the earthquake itself can cause active movement (a form of “live load”), apply forces to reshape or even break parts of the bridge, and cause or increase post-tension losses. But then when the earthquake is over, the piers of the bridge may have shifted, and that might permanently shift the way the bridge distributes its dead and live load.

- Temperature differentials. Concrete, like most materials, goes through thermal expansion and contraction as it warms and cools. But the entire bridge doesn’t heat and cool uniformly: the part in direct sunlight will warm quickly while the underside of the bridge will stay cooler. The windward side will experience wind chill; the leeward side far less so. On hot days the hollow interior of the bridge will probably take much longer to warm up, but once it’s warm it will probably stay so for much longer while the outside cools off at the end of the day. Similarly, the exterior of the bridge will cool much faster than the interior on a particularly cold day. So the West Seattle Bridge will not only see temperature changes that cause thermal expansion and contraction, it will do so at different rates in different parts of the bridge.

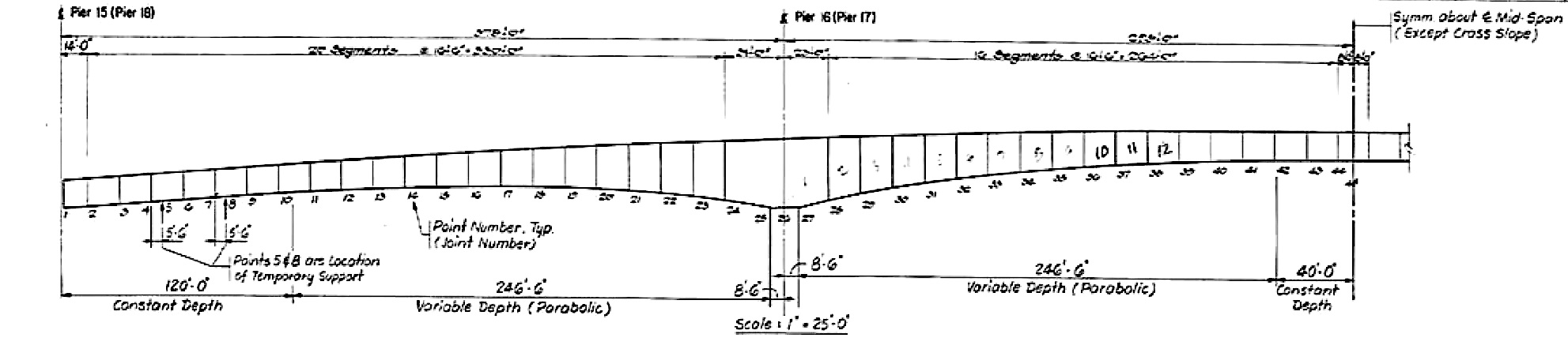

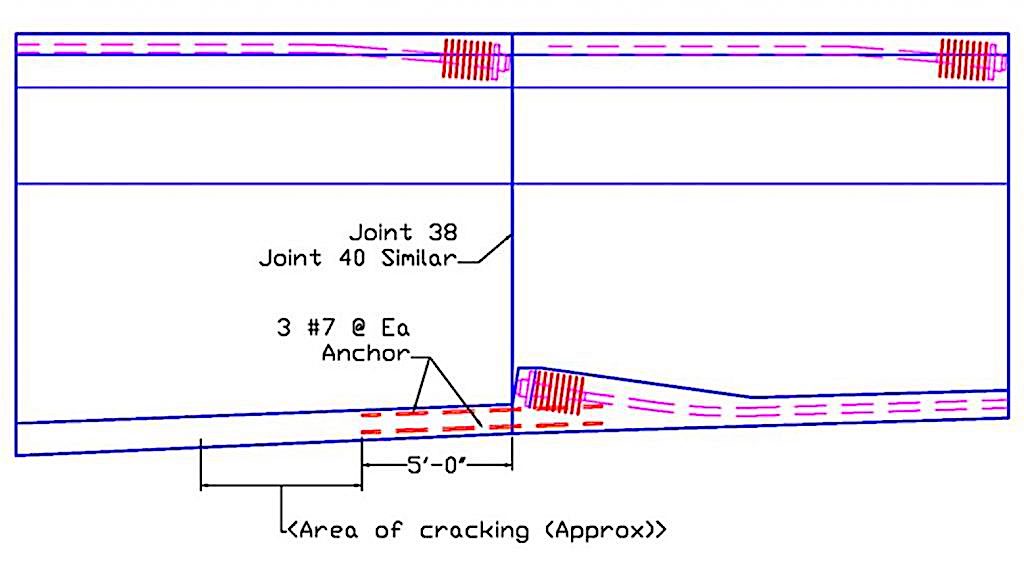

- Unique design elements of the bridge. The West Seattle Bridge main span is a cantilevered arch. That means it will generally have what engineers call a “positive moment”: the top of the bridge structure will tend to compress together, while the bottom of the bridge structure will tend to pull apart. It also has a “cantilever moment” (as I explained in my previous post): the part of the bridge farthest away from a pier could see the most physical movement, but the part closest to the pier could see some extreme stresses. Also, the post-tensioning steel tendons in the bridge terminate at the joint immediately after the segment where the most cracking is seen (Joint 38 and Segment 11 below), and a different steel structural support system is used to connect the segments after that — which if nothing else raises a whole set of questions about whether it was designed correctly, how the positive and cantilever moments are different at and beyond that point, and whether the stresses on the concrete change.

- A combination of some or all of the above — which is Donahue’s preferred explanation for the cracking issues.

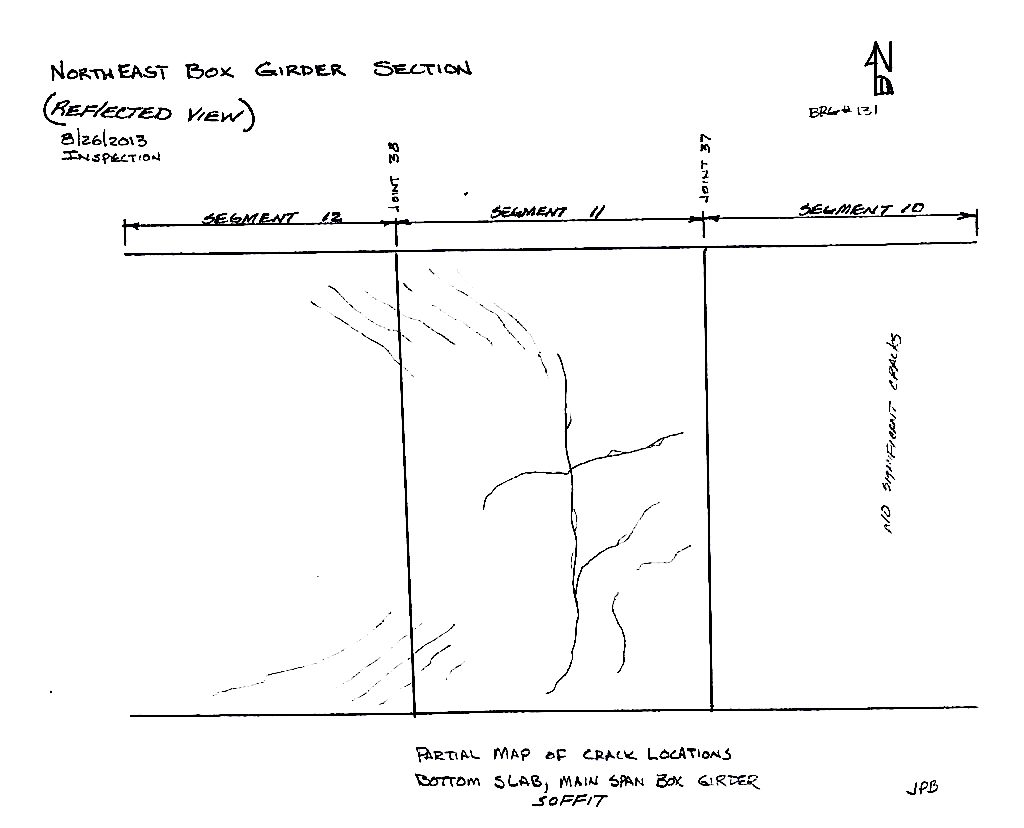

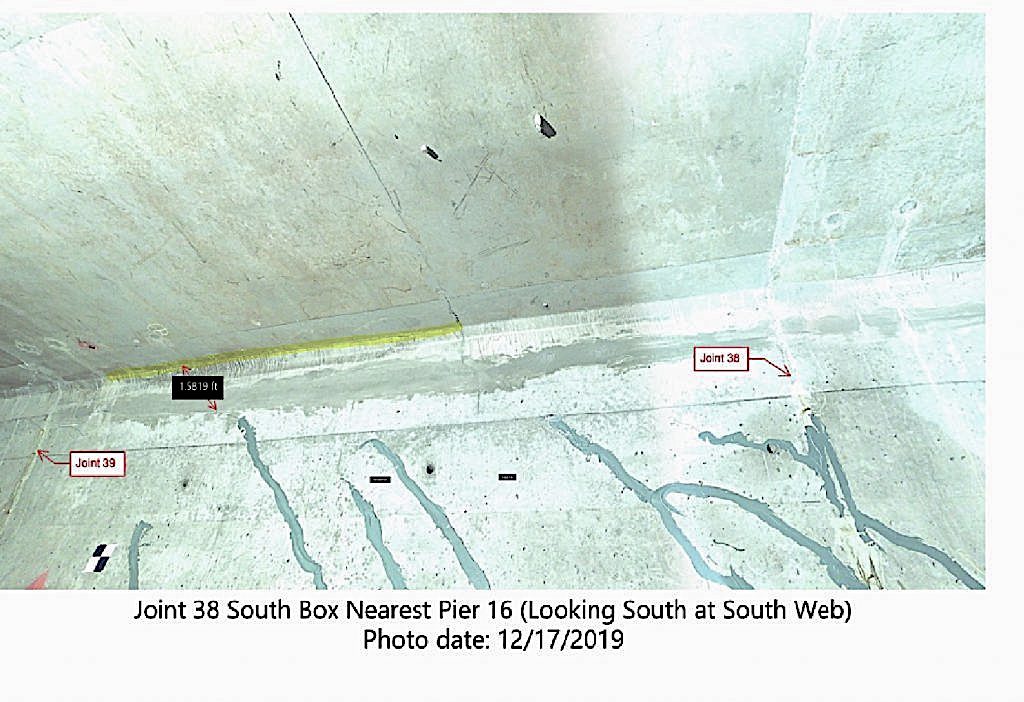

Since 2013, SDOT and its consulting engineers have found three different kinds of cracking in the bridge. First, there is cracking in the bottom (or “soffit”) of the box girder. This is what was first noticed on the underside of the bridge in 2013, and it led SDOT to bring in a consultant to try to determine the nature of the cracking. At the time, the cracks had not penetrated all the way through the bottom of the box to the interior floor, but in 2014 the SDOT inspector found that they had. The cracks work their way out diagonally from the middle to the edges of the bottom side. They all occur in Segment 11 of the bridge (on both sides of the main span) and traverse Joint 38 between segments 11 and 12.

Second, the concrete slab just below the top deck has horizontal cracks in it. These were first noted in the annual inspection reports starting in 2014, but were described as typical and minor — even though they appeared in most segments of the bridge span. Certainly this part of the bridge will experience Seattle’s wide range of weather, so one can expect a fair amount of thermal expansion and contraction. But to-date, SDOT has not determined exactly what caused the deck cracking.

West Seattle High Level Bridge Technical Assessment Memo March 2014

Third, some of the cracks in the bottom of the bridge extend up the sides of the bridge structure. The sides of the box girder have a different arrangement of steel supports than the floor, and the forces acting upon it are in different directions. So if the cracks extend up the sides, that potentially suggests a different set of forces acting on the bridge from the ones that cracked the bottom. Diagonal cracks up the south side of the bridge were noted in annual inspection reports starting in 2014 and were kept under observation, but did not raise serious concern until 2019 when they began to lengthen rapidly.

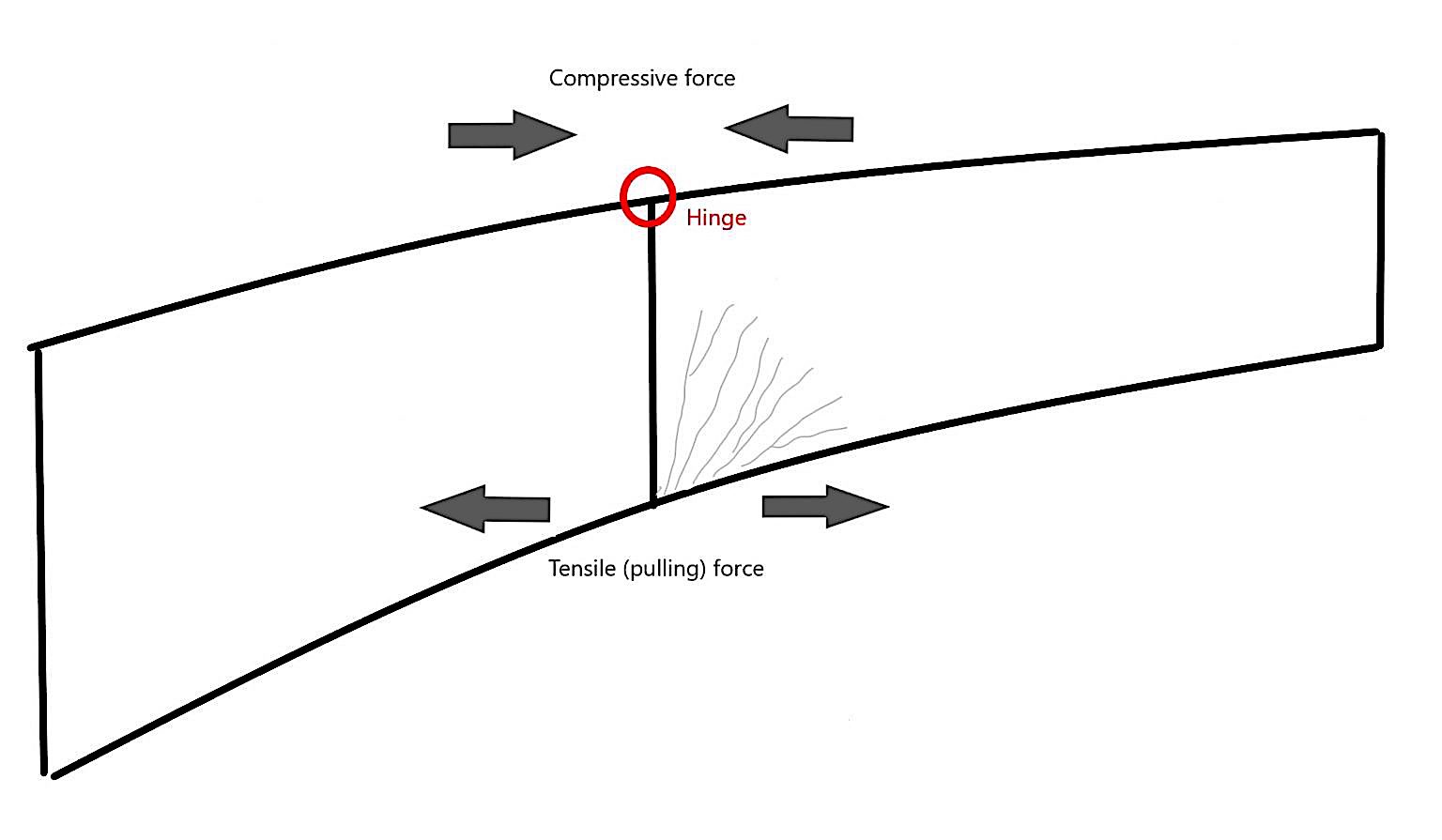

The bottom cracks, when discovered in 2013, raised enough concern to warrant annual inspections and the installation of remote monitoring equipment. But to be clear, the monitoring equipment only watched for widening of cracks, not lengthening. Given the “positive moment” of the bridge as we discussed earlier, the expectation is that the cracks on the bottom come from “tensile” or pulling forces. That’s why it’s important to monitor whether the cracks are widening: it would be an early sign that the concrete (and steel) is beginning to fail (so far the cracks haven’t widened appreciably). But cracks that run at 45-degree angles along surfaces, like the ones on the walls of the West Seattle Bridge, are a well-documented phenomenon, known as “shear cracks” — they generally happen next to vertical support columns when the area between the columns is not sufficiently supported and its load under gravity exceeds the wall strength. They can lengthen quickly and lead to rapid failure, so they need to be watched closely.

In December 2018, a consultant was brought in to inspect the monitoring system (which had seen some recent equipment failure) as well as the cracks. He noted that the cracks in the bottom of the box girder were not a structural concern — though they were a maintenance concern since they extended all the way through the concrete and could lead to corrosion of the steel tendons by letting air and moisture come into contact with them. But he also couldn’t determine whether the shear cracks in the walls — at the time showing slow growth over several years — were a cause for concern about the structural integrity of the bridge and its ability to carry a load.

Consultants memo from January 2018

The consultant also attempted to ascertain the cause of the cracking. The consultant who inspected the cracks in 2013 had much less information to go on, but with the steady progression of cracks by 2019 there was a clearer pattern. He observed that the original bottom cracks were also shear cracks but from a horizontal force instead of a vertical one, and the fact that the shear cracks are symmetrical (and mirror-image) on both sides of the span suggest that the force occurred equally in both directions. That strongly suggested to him that they were caused by twisting forces from an earthquake — perhaps the 2001 Nisqually quake — though again Donahue disagrees with this explanation and believes that it was a combination of factors. The consultant also concluded that the cracks on the side walls, which appear as continuations of the bottom cracks, were probably also created at the same time, but it potentially took several years for them to become large enough to be noticeable. He also suggested that after the initial creation of the wall cracks, their ongoing lengthening is probably due to gravity loads rather than more seismic activity, and is a function of the increased flexibility of the bridge at the bottom due to both the bottom and lower wall cracks — in other words, the more cracking exists, the more it’s likely to crack more.

In the consultant reports, they often describe the cracked segments of the bridge as creating a “hinge.” Imagine a hinge sitting on top of a joint between two bridge segments, with the “positive moment” compressive forces at the top holding it together, and the tensile forces at the bottom pulling it apart. Normally in an intact segment, the hinge doesn’t rotate, but with the added flexibility at the bottom due to the cracking, it’s easier for that hinge to start rotating — and the cracks will grow upward until they reach the top, splitting the segment and causing the bridge to fail. A quick reminder: the joint next to the cracking is Joint 38, which is one of the places where the main post-tension system terminates and a different system of steel girders is used to hold the segments together. When SCC Insight asked Donahue whether that might be a design flaw in the bridge, he said, “I wouldn’t characterize it that way,” suggesting instead that the “maximum moment” of the bridge — the locations where the stresses on the bridge are greatest and the structure is in most need of reinforcement — moved farther out on the cantilevered bridge than were originally calculated. So while the calculation of the maximum moment was done correctly according to 1980 standards when the bridge was designed, that may not have generated a correct result in the real world.

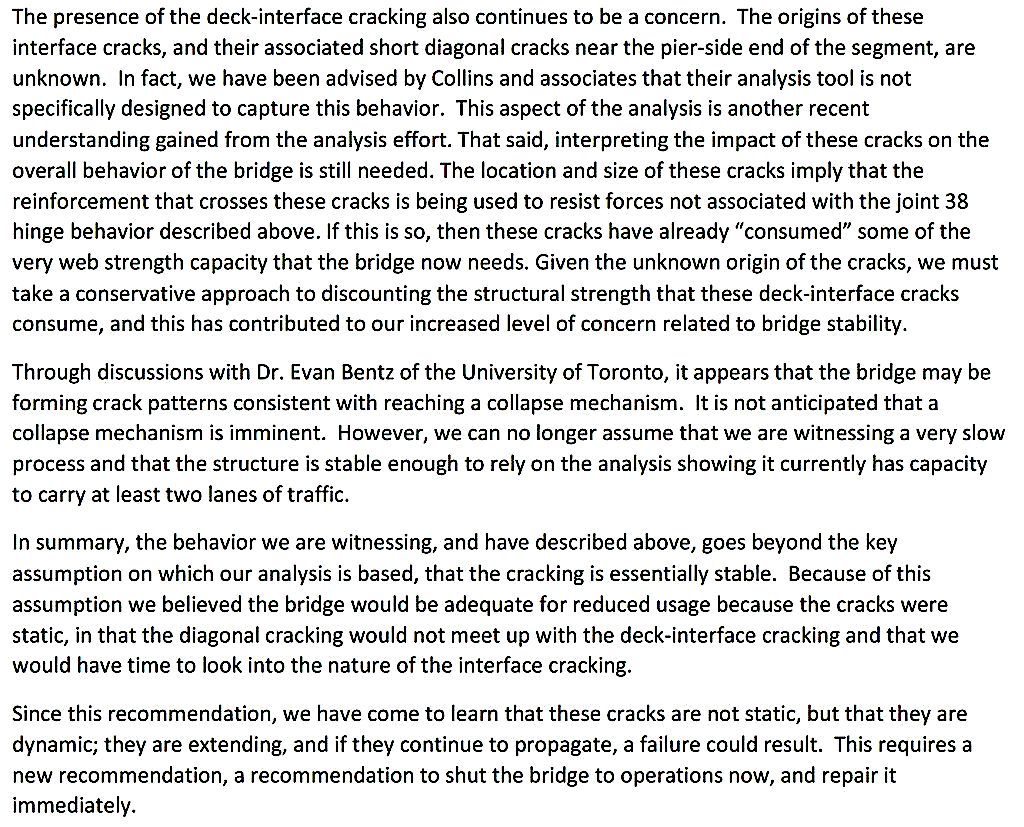

In February of this year, a different consultant team came in to analyze the load-bearing status of the bridge, driven by changes to federal bridge loading standards that required re-certification of the bridge. Upon inspection of the bottom and side cracks and understanding the hinge system this created, they became very concerned that the “live load” on the bridge driving over that hinge would constantly rotate it small amounts back and forth and accelerate the cracking. So they recommended that SDOT lower the load on the bridge (i.e. close some lanes) to reduce the hinge rotation.

WSP Consultants Memo Feb. 21, 2020

But when they returned in March, they discovered that the cracking had accelerated — and in some places was only about a foot away from the existing cracks in the deck.

They realized that if the wall cracks continued to grow up into the deck cracks, that could trigger a bridge failure, because it would then be split all the way through from top to bottom. So they called for the immediate closure of the bridge, both for safety and to reduce the “live load” on the bridge to zero in order to reduce or stop further cracking until it can be repaired.

WSP Consultants Memo March 2020

Was SDOT proactive enough throughout this seven-year process? Probably. The consultants they brought in consistently told them that the bottom cracking was not a structural concern, but the walls cracks could become one if they grew. SDOT took that to heart, increased the frequency of its inspections, and installed crack monitors.

The inspection reports do raise a couple of yellow flags, though. First, they point out that there were several long-standing maintenance issues, some of which were reported year after year. That includes broken fencing around the bridge piers, water leaks, and unusable fall protection equipment. Most notable is the water main and fire suppression piping, which are hung on wire hangers along the bridge’s interior span. Every inspection report from 2014 to the present notes that the hangers have been damaged throughout the bridge, no longer hang vertically as originally installed, and because of that the piping system shows signs of stress. Donahue pointed out that SDOT dramatically under-funds ongoing maintenance for fixed assets such as bridge structure; the standard for budgeting for annual maintenance is 1-3% of the value of the structures being maintained. Donahue’s department manages $8.3 billion of bridge structures; if fully funded, that would equate to an annual maintenance budget of at least $83 million. In contrast, his maintenance budget is only $7 million. It should be no surprise that there is a substantial amount of deferred maintenance in the city’s bridges and other transportation infrastructure.

Second, the SDOT inspection reports for 2014 through 2016 are largely identical — down to the typos and references to “last year” that got copy-and-pasted from the 2014 report to the subsequent years. Now, there are a ton of minute details in those reports and I fully sympathize with an inspector who doesn’t want to type them all in by hand again if nothing has changed, but it gives the strong impression that the 2015 and 2016 reports were not carefully written and causes one to question whether they faithfully represent the state of the bridge at the time. The inspections were conducted by the same two people in those years. In later years some different inspectors cycle through, and less content is copied over (and when it does the typos get fixed).

Third, it appears that the interior of the bridge was only inspected every other year, though the exterior was inspected annually. Since one of the ongoing issues was the extent to which the cracks extended all the way through the concrete, one would think that SDOT would have done an interior inspection every year.

Last question: what happens from here? Donahue said that he has two contractors authorized to help with the planning and repairs, but at the moment the first priority is a new issue that has appeared: one of the piers of the bridge (Pier 18, which is not one of the two supporting the main span) has a “locked lateral bearing.” A bridge bearing is a flexible platform that the bridge sits on top of which supports its weight but allows for small amounts of movement in certain directions due to wind, thermal expansion and contraction, and seismic activity. When a bearing “locks,” that means it is no longer allowing movement as intended — which could add more stress onto the bridge structure. Donahue said that they are expediting that repair, and once the bearing is fixed then they will get to work on shoring up the cracked sections of the bridge. In the meantime, he said that his team is conducting near-daily inspections to continue to map the cracks and refine their understanding of the issues. They are also about to launch an expanded instrumentation program to obtain finely-detailed stress and crack data about the entire system of cracking: the deck, the walls, and the bottom, so that they can design a repair that will fix the whole system.

SDOT will be delivering a report to Mayor Durkan later this month. That report will detail the potential scenarios in which the bridge might fail, so that if it continues to deteriorate toward failure in a manner that SDOT can’t control, the city knows how to react.

A couple of closing thoughts. First, the bridge was not in danger of imminent collapse. It was clearly on a path to failure, but looking at the rate of further cracking, it was probably weeks away when the recommendation came on March 20. That’s still scary and SDOT did the right thing in closing the bridge that day, but between 9am that morning when the recommendation was made at 7pm that evening when the bridge was closed, no one was in mortal danger because they drove across the bridge.

Second, SDOT is to be commended for publicly posting all of the reports so the public can read them. It gives us hope that they will continue to be that transparent as they work through the repair plans.

I hope you found this article valuable. If you did, please take a moment to make a contribution to support my ongoing work. Thanks!

Comments

Well written.

Well written.

Hello, thanks for this…

Hello, thanks for this analysis. Do you know whether anyone has measured seismic activity due to the Nucor plant right next to the bridge? Anyone living close to the plant can tell you that there are often “booms” due to the plant. Sometimes the tremors are significant enough to knock things off shelves as noted in past West Seattle blog posts (search Nucor). I wonder if they would have an impact on the bridge. Thanks again

Reports such as this are…

Reports such as this are important as the public has a right to know the details. Well written article. Keep us posted on the plans for repair and timelines.

great article, I know you will continue to keep us informed