SDOT will do 'microsurfacing' project in Arbor Heights and Fauntleroy this summer

While the exact streets are yet to be determined, SDOT will be conducting a micro surfacing maintenance project in these areas this summer.

Wed, 01/08/2014

SDOT will conduct a microsurfacing preventative maintenance project on selected blocks in Arbor Heights and Fauntleroy this summer. In preparation for this project, SDOT will start to make minor repairs to selected blocks as early as this month. That will mean potholes and other pavement defects will be repaired prior to the other work.

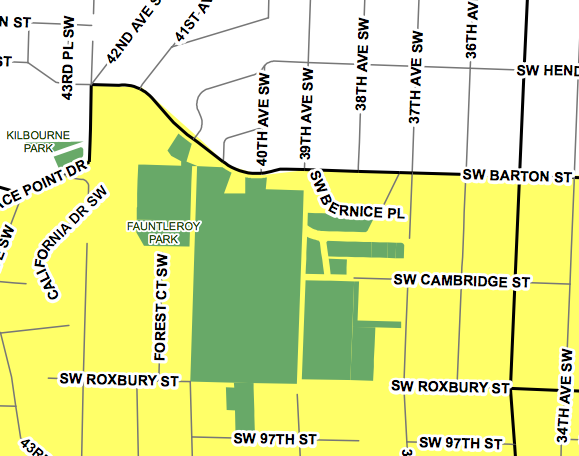

The 2014 project is bounded roughly by:

- Puget Sound to the south and west

- SW Brace Point Dr and SW Barton St to the north

- 30th Ave SW and Seola Beach Dr SW to the east

For a map of the 2014 project area see the link above.

Project Schedule

January – Summer of 2014: Preparation

To prepare the streets for microsurfacing, SDOT crews will make minor repairs such as filling potholes, depressions and cracks. Locations identified as candidates for such repairs may be marked with white paint.

Trees and vegetation will be trimmed as necessary to allow the microsurfacing crews to complete their work.

The project area is divided into five sections. The northeast section will be prepared first, and SDOT will prepare each section before moving onto the next.

The prep work will begin as early as January as weather permits and may continue into the summer. This work is expected to occur intermittently as SDOT deploys crews for this project and for other maintenance projects throughout the city.

Access to all homes will be maintained during this preparation phase.

Summer 2014: Seal Coating Work

Streets will be swept and the microsurfacing seal coat will be applied.

Traffic Markings – where covered up - will be re-painted.

What is Microsurfacing?

Microsurfacing is a protective seal coat which extends the life of pavement. It is a thin, tough layer of asphalt emulsion blended with finely crushed stone for traction.

This is a cost-effective method to renew the road surface and seal minor cracks and other irregularities. This preventive maintenance process protects the pavement from moisture penetration and oxidation.

Similar to painting a house, microsurfacing creates a protective layer which preserves the underlying structure and prevents the need for more expensive repairs in the future.

Microsurfacing is seeing growing use by transportation agencies, including SDOT.

An Alternative to Chip Sealing

In the past, SDOT’s primary method of preventive maintenance has been chip sealing. While chip sealing is an effective preventive maintenance measure, it leaves the roads very rough and there is an extended period of loose rock on the street. Microsurfacing and chip sealing are both seal coats that extend the life of the pavement for about the same amount of time (5 to 10 years).

However, microsurfacing has two key advantages over chip sealing:

No loose rock chips are involved, so there is no need to sweep loose rocks weeks after the project is complete.

The final product provides a finished surface which is black in color and looks similar to a conventional asphalt surface.

Chip sealing has the advantage that you can drive on the street immediately, but with microsurfacing you must wait two hours or more for the surface to cure before driving or walking on it.

How Residents May Be Affected During Microsurfacing

ONE DAY ROAD CLOSURES

Hours

On the scheduled date of seal coat work, the full width of the block will typically be closed for two to three hours. During this closure time the contractor will sweep, apply the microsurfacing seal coat, and allow the microsurfacing to cure.

These two to three hours could occur at any time during the project’s work hours, but we won’t be able to predict exactly when they will occur for a particular block. This will depend on how quickly other blocks scheduled for that day are completed.

“Road closed” signs may be posted on a block for up to a full workday. However, before and after the period of seal coat application and curing, you can walk or drive on the street with assistance from crews. Crews will work to minimize delays and provided assistance navigating around the work zone.

If you need to access your car, it's best to park it on another street for the day.

Sidewalks will remain open at all times.

Wait to Use the Street

It typically takes about two hours for the microsurfacing to cure. No parking and road closed signs will be removed as soon as the contractor believes it is safe to travel on the road. In addition to vehicular traffic, you should refrain from walking, biking or bringing pets on the street.

PARKING RESTRICTIONS

No parking signs will be installed at least 72 hours before the start of work. On the day a block is scheduled for work, residents will not be allowed to park on the street.

No Driveway Access

Driveway access will be blocked for up to two hours. Once the microsurfacing is placed there is no access out of or into driveways during the curing period. Because we do not know in advance what part of the day this period would occur, if you need your car during that day, SDOT recommends parking on a block that is not scheduled for microsurfacing on that day.

Garbage, Yard Waste and Recycling Collection

If the microsurfacing project is scheduled on a day when solid waste is normally picked up on a particular block, SDOT will coordinate to have solid waste picked up during a specific period of time during that day.

Some blocks NOT receiving microsurfacing may be affected

On the day of the work, adjacent blocks may have more cars parked on the street and residents may need to navigate around the closed streets.

Access on a small number of adjacent blocks may be impacted at a similar level to access on the blocks receiving microsurfacing.

It Could be a Rough Road for a Bit

In general, right after microsurfacing, the road may have a slightly coarse driving surface. As cars drive over the road, however, the surface will become smoother, but still have enough traction to provide skid resistance.

Full information available on the SDOT Microsurfacing Page here.